Aluminum trim is a popular material used in various industries such as automotive, construction, and furniture. It serves both functional and aesthetic purposes and provides numerous benefits to these industries. In this article, we will explore the creation, variations, considerations regarding its creation and use, benefits, and applications of aluminum trim. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

Since 1948, Johnson Brothers has been a leader in the aluminum roll forming industry. Our tooling can form different shapes with multiple bends & double thicknesses making a stronger part. Choose your type of outside edge, including hemmed designs. Our manufacturing procedure can take your part from concept to achievement. Please contact us today with any questions.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Aluminum Trim Manufacturers

What Is Aluminum Trim?

Aluminum trim is a type of aluminum extrusion or a flat piece of aluminum that has been shaped or cut to fit specific applications. The primary purpose of aluminum trim is to provide a finished look to products or to cover rough edges, corners, or gaps. It is often used as a decorative element, but it also serves as a protective barrier that prevents moisture, dirt, or debris from entering the product.

How Is Aluminum Trim Created?

There are various methods used to create aluminum trim, including extrusion, rolling, stamping, and CNC machining. Each process has its advantages and disadvantages, and the selection of a specific process depends on the application.

Extrusion

Extrusion is the most common method used to create aluminum trim. In this process, a heated aluminum billet is forced through a die to create a specific shape. Extrusion allows for intricate designs and is ideal for producing large volumes of aluminum trim.

Rolling

Rolling is another method used to create aluminum trim. In this process, a flat piece of aluminum is passed through a series of rollers, which shape it to the desired dimensions. Rolling is ideal for creating flat pieces of aluminum trim.

Stamping

Stamping is a process that uses a mold to create aluminum trim. The aluminum is placed between the mold and a press, which applies pressure to form the aluminum into the desired shape. Stamping is an ideal cost effective solution for creating small volumes of aluminum trim.

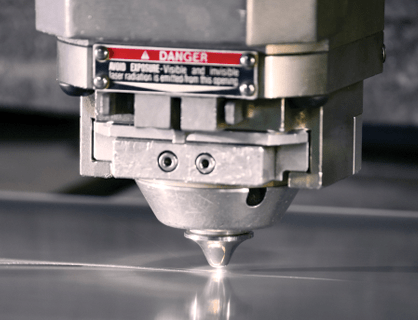

CNC Machining

CNC machining is a process that uses computer-controlled tools to cut and shape aluminum trim. This method is ideal for creating precise and intricate designs, but it is costly and time-consuming.

Are There Variations of Aluminum Trim?

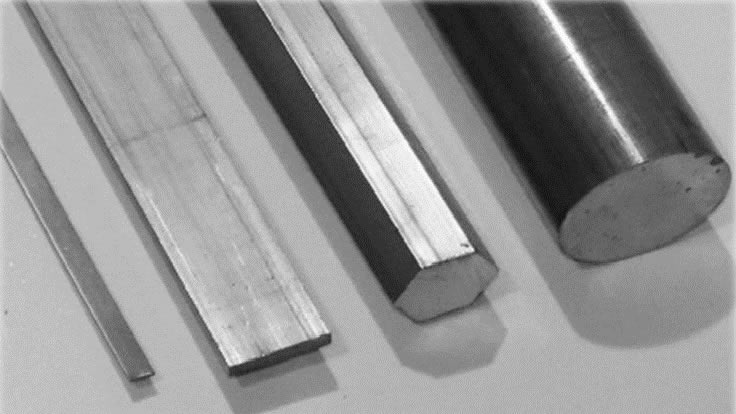

Aluminum trim comes in various forms, including angles, channels, tubes, rods, and sheets. Each variation has specific characteristics that make it ideal for specific applications. Angles are L-shaped aluminum trim that is ideal for covering sharp corners and edges. Channels are U-shaped aluminum trim that is ideal for providing a finished look to products. Tubes are cylindrical aluminum trim that is ideal for creating structures or as a conduit for wires. Rods are cylindrical aluminum trim that is ideal for decorative purposes. Sheets are flat aluminum trim that is ideal for covering large surfaces.

What Considerations Are There Regarding Aluminum Trim?

The creation of aluminum trim has some considerations to take into account, including its environmental impact. Aluminum production requires a significant amount of energy, and the extraction of bauxite, the primary source of aluminum, can have negative effects on the environment. Additionally, the use of aluminum trim can contribute to waste if not disposed of correctly.

What Are the Benefits of Aluminum Trim?

Despite the negative considerations, aluminum trim provides numerous benefits, including its lightweight and durable nature. It is also corrosion-resistant, making it ideal for outdoor use. Aluminum trim is versatile and can be easily painted or anodized to match any color scheme. It is also cost-effective and can be recycled, reducing waste and contributing to sustainable manufacturing practices.

What Are Some Applications of Aluminum Trim?

As a result of these benefits, aluminum trim has numerous applications in various industries, including the automotive, construction, furniture, packaging, and aerospace industries. Each of these applications are explained in greater detail below.

Automotive Industry

In the automotive industry, aluminum trim is used to provide a finished look to cars and as a protective barrier against moisture and dirt. It is commonly found on the exterior of the car, including around windows, doors, and the trunk. Aluminum trim is also used in the interior of the car, such as on the dashboard, door panels, and seats. In addition to its aesthetic appeal, aluminum trim also provides a protective barrier against scratches, chips, and dings.

Construction Industry

In the construction industry, aluminum trim is used as a decorative element in buildings and as a protective barrier for windows and doors. It is commonly used on the exterior of buildings to provide a finished look and to protect against moisture, dirt, and other environmental factors. Aluminum trim is also used in the interior of buildings, such as on baseboards, door frames, and window frames. It is popular in modern architecture due to its sleek and minimalist appearance.

Furniture Industry

In the furniture industry, aluminum trim is used to provide a finished look to furniture and as a structural element. It is commonly found on chairs, tables, and cabinets. Aluminum trim is also used on outdoor furniture due to its corrosion-resistant nature. It is popular in contemporary furniture design due to its modern and industrial appearance.

Packaging Industry

In the packaging industry, aluminum trim is used to create lightweight and durable packaging for products. It is commonly used in the food and beverage industry to create aluminum cans and foil packaging. Aluminum trim is also used in the pharmaceutical industry to create packaging for medicine and medical devices. Its lightweight nature makes it ideal for shipping and reduces the environmental impact of transportation.

Aerospace Industry

In the aerospace industry, aluminum trim is used to create lightweight components for aircraft. It is commonly used in the manufacturing of wings, fuselages, and landing gear. Aluminum trim is also used in the interior of aircraft, such as on seats and overhead compartments. Its lightweight nature reduces the weight of the aircraft, improving fuel efficiency and reducing emissions.

Choosing the Proper Aluminum Trim Manufacturer

To ensure you have the most productive outcome when purchasing aluminum trim from an aluminum trim manufacturer, it is important to compare several companies using our directory of aluminum trim manufacturers. Each aluminum trim manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each aluminum trim business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple aluminum trim companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services