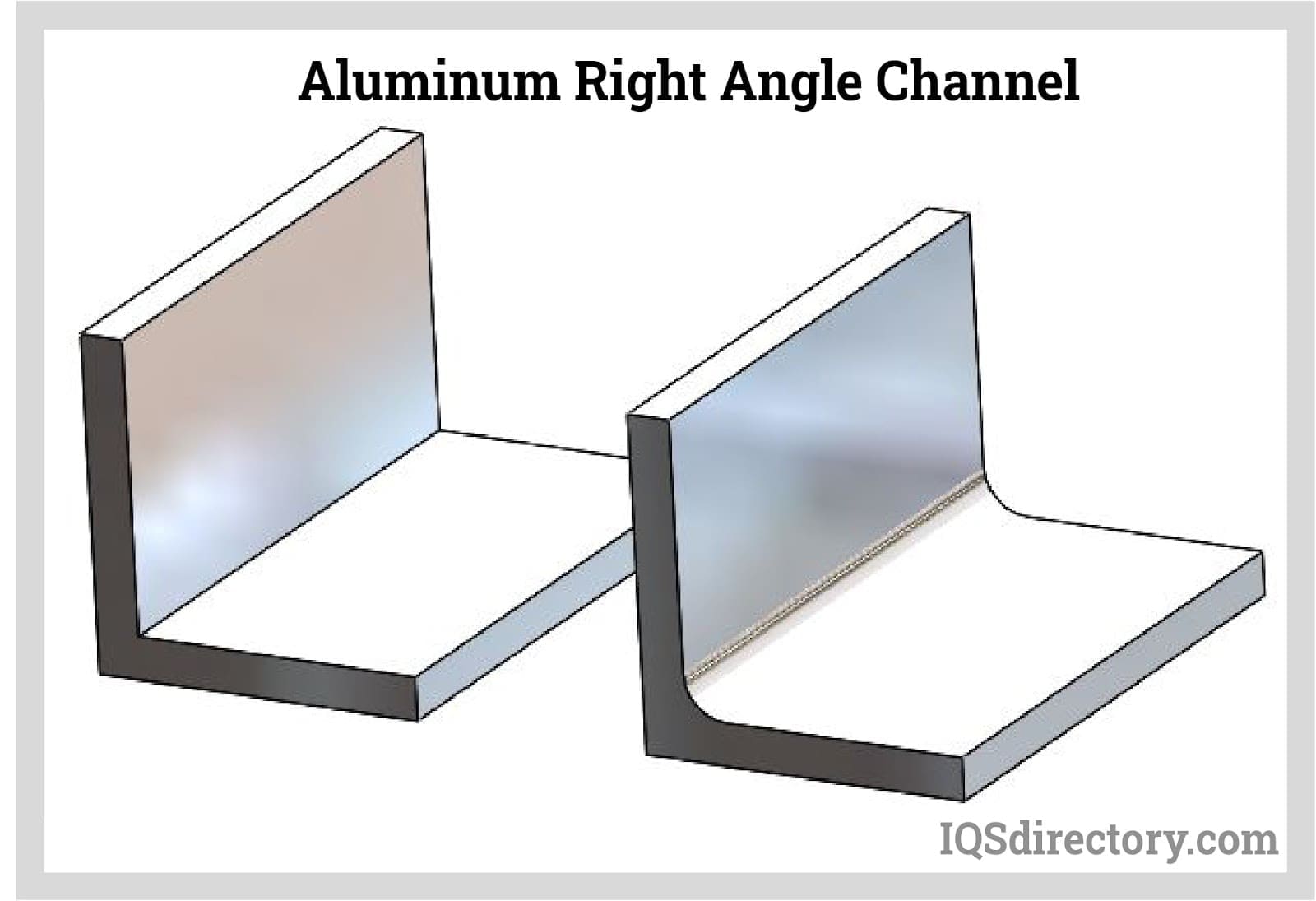

A device called an aluminum angle has two legs that meet at a 90-degree angle. This product can be utilized for general fabrication as well as structural purposes. Since aluminum ore is the most common metal one may encounter on earth, they are readily produced. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

Since 1948, Johnson Brothers has been a leader in the aluminum roll forming industry. Our tooling can form different shapes with multiple bends & double thicknesses making a stronger part. Choose your type of outside edge, including hemmed designs. Our manufacturing procedure can take your part from concept to achievement. Please contact us today with any questions.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Aluminum Angle Manufacturers

What are Aluminum Angles?

However, Bayer and electrolytic processes must be employed to refine commercial aluminum numerous times before it can be utilized to manufacture goods. Once it has been processed, however, it has non-corrosive, non-toxic, non-magnetic, non-combustible, and non-sparking physical features that give it a high strength-to-weight ratio.

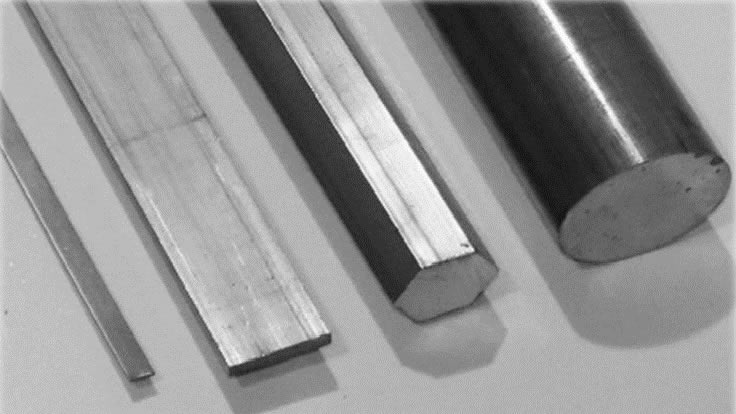

Extrusion of Aluminum

Aluminum is extruded to produce uniform aluminum sections that are cut and welded together to form various angles and forms. The tungsten electrode method is used to join two pieces of aluminum that are the same size or different diameters. As required, each L-shape has a 90-degree angle. The extrusion method involves forcing metal billets through a die at various temperatures to create structural pieces with long, constant cross sections. Extrusion operations can be divided into three categories based on temperature: hot extrusion, warm extrusion, and cold extrusion.

Warm extrusion occurs at relatively high temperatures, cold extrusion occurs at or very close to room temperature, and hot extrusion is used for extrusion operations that occur at high temperatures. Because it might be challenging to extrude an L-shape, the legs of the aluminum angles are frequently welded together after the extrusion process. TIG welding is one of the welding techniques applied in this procedure. TIG welding is an arc welding technology that creates a weld using a tungsten electrode that is not consumable.

Additionally, aluminum angles are frequently T5 or T6 tempered (two common heat-treatment processes used with aluminum in order to make it more suitable for various production purposes) to acquire the appropriate strength for structural applications. Anodizing, a finishing procedure where aluminum is oxidized in a chemical bath to form a durable outer coating, is frequently used on structural aluminum angles.

Types of Aluminum Angles

The different types of perforated angles include:

Perforated Aluminum Angles

Perforated aluminum sheets, which are highly corrosion resistant, heat and light reflective, and are ideal for applications requiring formability and ductility, are used to make perforated aluminum angles. Different surface treatments can be used. Aluminum with holes is frequently anodized to increase strength and color. However, there is typically no need for a protective coating. Low temperatures are suitable for the material's operation. At temperatures below 0 °F, ductility is preserved and total strength rises.

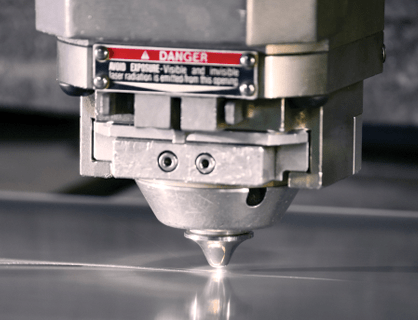

When temperatures exceed 400°F, the aluminum alloy starts to weaken. The width of perforated sheets can reach 60 inches. Rotary perforating-pin rollers, die/punch presses, or lasers are used to perforate the aluminum sheet.

Slotted Aluminum Angles

Aluminum sheets are machine-pressed into a slotted angle shape and then hole-punched. Standard lengths are produced for the strips. The 90-degree right angle is created by longitudinally folding the metal strips to create the slotted angles. On both sides of the slotted (pierced) aluminum angle, holes have been drilled at predetermined or standard intervals. Normally, the holes are separated by one inch (2.54 cm), measured center to center. Oval-shaped holes allow for a range of stresses to be placed on the end product.

Vertical commercial shelving sections frequently feature slotted angle pieces. The shelving is simple to put together using nuts and bolts thanks to slotted metal angles. A lightweight, architectural-grade slotted angle system is made of reusable metal strips with uniformly-sized, elongated punch holes.

6061 and 6063 Aluminum Angles

Both 6061 and 6063 aluminum angles are alloyed with silicon and magnesium. Both alloys are commonly extruded, exhibit good weldability, and generally possess good mechanical properties. Angles made of 6061 aluminum often have rounded corners, but those made of 6063 aluminum typically have sharp corners that represent their common usage.

Round-cornered 6061 aluminum angles, the stronger of the two, are mostly utilized in structural applications. Since they can be anodized successfully by covering them with a protective coating, 6061 aluminum angles resist stress and cracking, have above average corrosion resistance, are non-magnetic, are easily machined, and may be welded. Due to these properties, angles made of 6061 aluminum are used in various braces and supports.

Although its strength capacity is not as great as its brother, 6063 aluminum is actually the more common alloy used for aluminum extrusion. 6063 aluminum angles are commonly found in architectural trim, machine parts, construction appliances, and automotive appliances.

Choosing the Correct Aluminum Angles Manufacturer

To make sure you have the most productive outcome when purchasing Aluminum Angles from an Aluminum Angles Supplier, it is important to compare at least 5 Manufacturers using our list of Aluminum Angles manufacturers. Each Aluminum Angles Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Aluminum Angles business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Aluminum Angles companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services