The most common aluminum alloy used as structural aluminum is 6061-T6, which is an alloy in which aluminum, manganese and silicone are the major elements. Although structural aluminum is more costly than other metals, it has a much quicker manufacturing process and low cost of labor. Benefits of structural aluminum include that it is clean and an aesthetically-pleasing material without the addition of painting or other methods of further finishing. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Structural Aluminum Manufacturers

Structural aluminum is commonly used in the marine, automotive, engineering and construction industries to produce machine bases, building structural framing, cryogenic vessels, piping, bridges and industrial machinery.

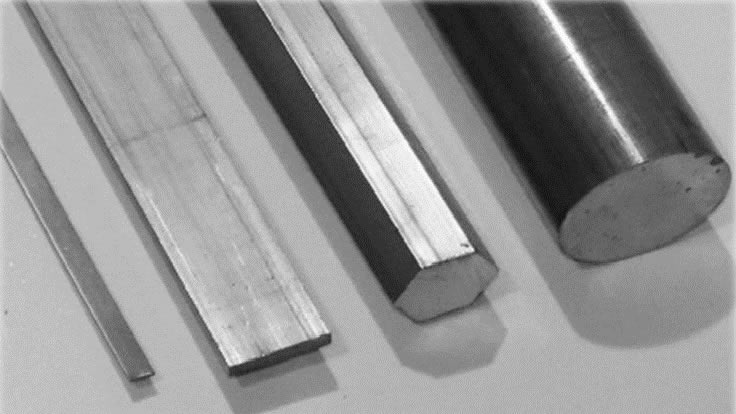

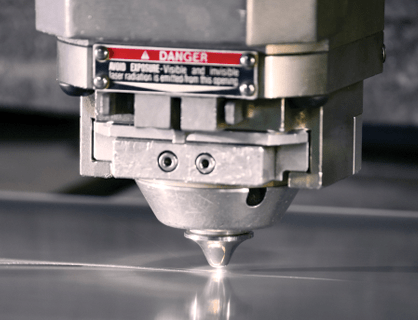

In addition, structural aluminum can be formed into many different shapes, including castings, forgings, wire, rod, bar and flat rolled sheets (thinner than .25 inches) or plates (thicker than .25 inches). Extruded aluminum is stronger and more durable than other kinds of aluminum because of the way in which it has been machined. The extrusion process entails forcing round aluminum stock called "billets" by means of a ram through a die. A die is a hollow profile that shapes the aluminum into a specific extruded shape as the billet is squeezed through. In addition to the extrusion process, structural aluminum is also put through cold working and heat treatments after forming to increase these properties. Aluminum may be cold rolled, drawn, straightened or flattened, all of which are done at or around room temperature.

When cold-worked, a negative is that aluminum will often lose some of its ductility in the process. All of these processes change the internal grain characteristics and increases tensile strength, yield strength and hardness. To obtain the desired strength, structural aluminum is heated at a high temperature for a certain amount of time, then quickly cooled by quenching, which is immersing the metal in cool water. Age hardening also increases aluminum's properties. In this process, the metal is slowly heated and kept at that temperature for a long period of time, strengthening the aluminum's grain.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services