Aluminum tubing may also have rectangular, square or round cross-sections. Formed during extrusion processes, aluminum tubing may be hot extruded, cold extruded or warm extruded, all of which extrude aluminum through a die, although at various temperatures. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

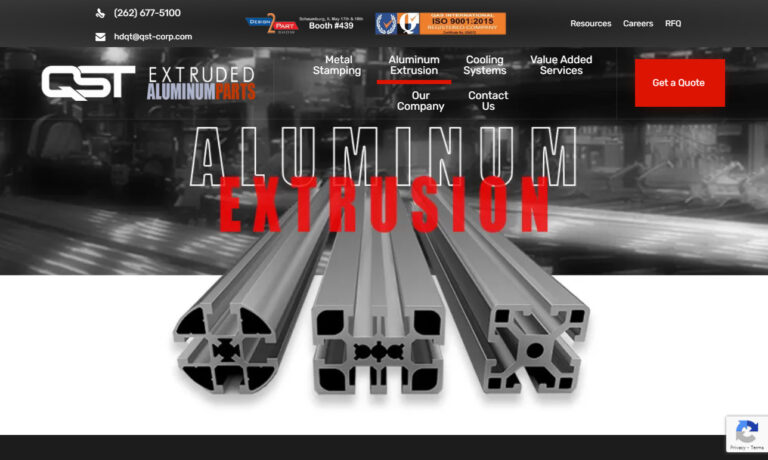

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Aluminum Extruded Tubing Manufacturers

Due to the variety of processes and shapes, aluminum extruding tubing has a wide range of applications such as mining equipment, hardware joints, fluid and gas transport, light building frames, structural applications, lighting fixtures and light poles. In addition, aluminum tubing has advantageous characteristics such as having high electrical conductivity and being a good heat conductor and reflector, which make it ideal for both heat transfer and heat shield applications.

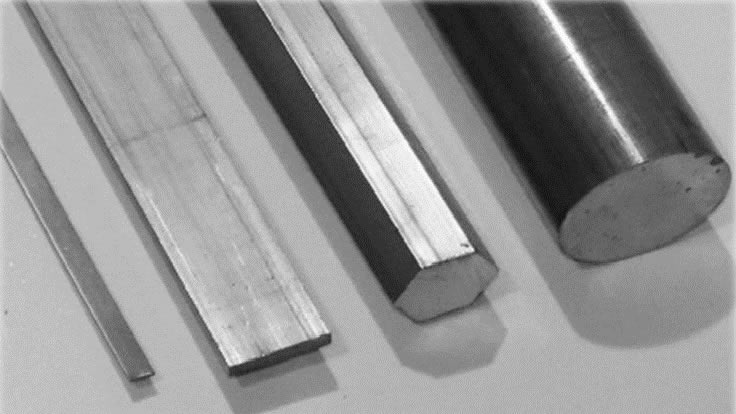

Additionally, industries that benefit from aluminum tubing's flexibility and high strength-to-weight ratio include construction, industrial manufacturing, medical, aerospace, automotive, petrochemical and food processing. Aluminum; tubing is formed during the extrusion process, in which round aluminum stock called "billets" or "logs" are pressed by a ram through a die, which is a hollow profile that shapes the aluminum into a specific extruded shape as the billet is squeezed through. Aluminum extrusion processes include hot extrusion, cold extrusion and warm extrusion. In cold extruding, an aluminum billet is pressed through the die at room temperature or, at least, very close to room temperature. Warm extruding, on the other hand, is done on billets brought to temperature ranges between 800 and 1800 degrees F. Lastly, hot extrusions are performed on aluminum which has been fully plasticized by heat and is often performed in a vacuum to avoid oxidation. In addition, aluminum can be extruded through the die using two different methods of extrusion: indirect extrusion and direct extrusion. Direct extrusion holds the die stationary while the ram forces the aluminum alloy through the die opening, while indirect extrusion holds the die stationary as the hollow ram moves into the stationary billet from one end, forcing the metal to flow through the die. After the aluminum tubing has been extruded, it is straightened by a stretcher.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

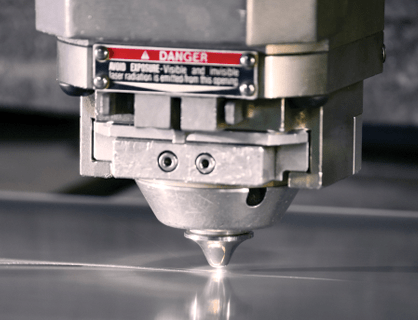

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services