As practical thermal energy solutions for both low and high volumes, extruded heatsinks are utilized in a wide range of applications including refrigeration, heat engines, cooling medical devices, lasers and CPUs. Heatsink applications are useful for industries that require efficient heat dissipation such as electronics, military, medical equipment, industrial manufacturing, appliance and LED lighting. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Heatsink Manufacturers

This product can vary in many aspects of design, including length, noise level, speed, width, style, height and weight. There are also different styles of heatsinks including stamped heatsinks, bonded heatsinks and folded heatsinks that are much less cost-effective to manufacture than extruded heatsinks. In addition, larger heatsinks absorb more heat that smaller heatsinks due to the relationship between the heatsink's surface area and ability to rapidly dissipate heat.

Extruded heatsinks are typically made of aluminum, specifically aluminum alloys such as 6061 aluminum and 6063 aluminum. The most common design of extruded aluminum heat sinks is of a flat aluminum base with vertical radiating fins for increased surface area. Three items are needed for the rapid transfer of thermal energy: a heatsource, a thermal compound and a heat sink. The heatsource, an object at a relatively high temperature, must be thermally bonded to the base of the heat sink by a thermal compound for the heat transfer to work.

Thermal compounds are generally a paste-like substance constructed with particles of silver, since silver has a very low thermal resistance. Once bonded, heat transfer begins and brings the heatsource into thermal equilibrium with the heatsink, thus lowering the temperature of the heatsource. Extruded heatsinks can be passive or active. Active heatsinks use a power source such as integrated fans with directed fins that direct airflow patterns in order to help to increase the surface area of the heatsink. Passive heatsinks do not use any mechanical components, and the heat is dissipated through convection, or the transfer of heat through a liquid or gas that is caused by molecular motion.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

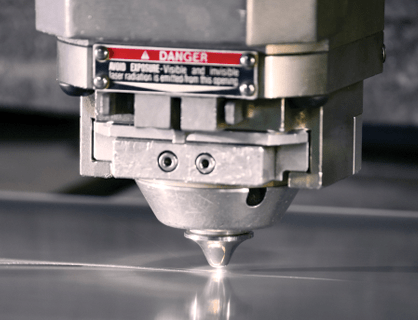

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services