The profiles for aluminum extrusion are produced by dies configured and crafted to represent the desired design of the extruded product. They come in sizes and dimensions capable of meeting the requirements of any application. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

Since 1948, Johnson Brothers has been a leader in the aluminum roll forming industry. Our tooling can form different shapes with multiple bends & double thicknesses making a stronger part. Choose your type of outside edge, including hemmed designs. Our manufacturing procedure can take your part from concept to achievement. Please contact us today with any questions.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Aluminum Profile Manufacturers

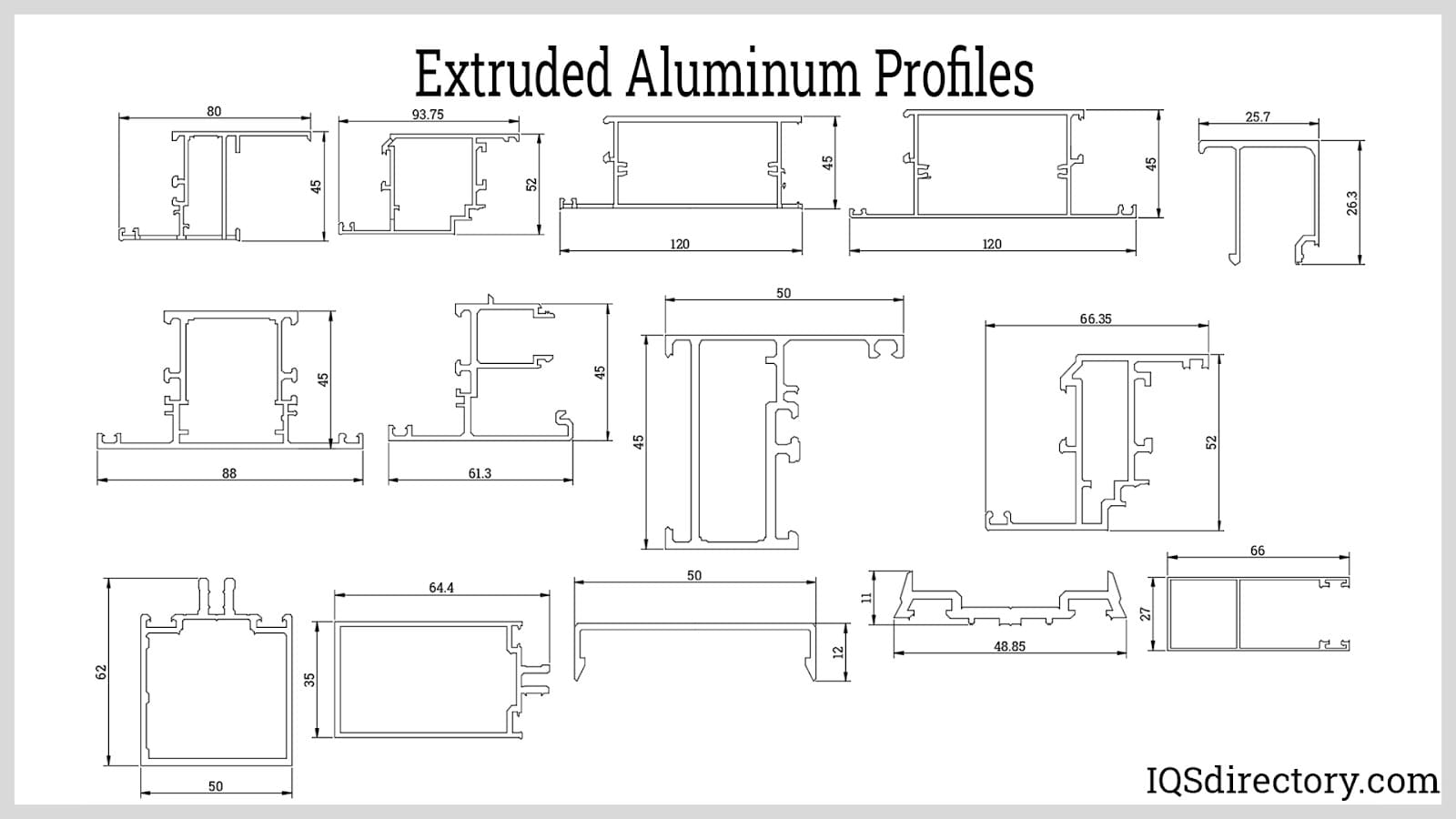

Aluminum profiles are made from hardened steel, making it possible to use the same profile multiple times without fear of degradation. Essentially, a profile produces continuous high tolerance components consistently. Common standard profiles include I beams, angle brackets, and tubes. Aside from the standard profiles, unique profiles are created to meet the needs of specific applications. In those cases, customers supply a computer-created rendering or work with extrusion engineers to develop the desired profile.

Manufacturing a Profile

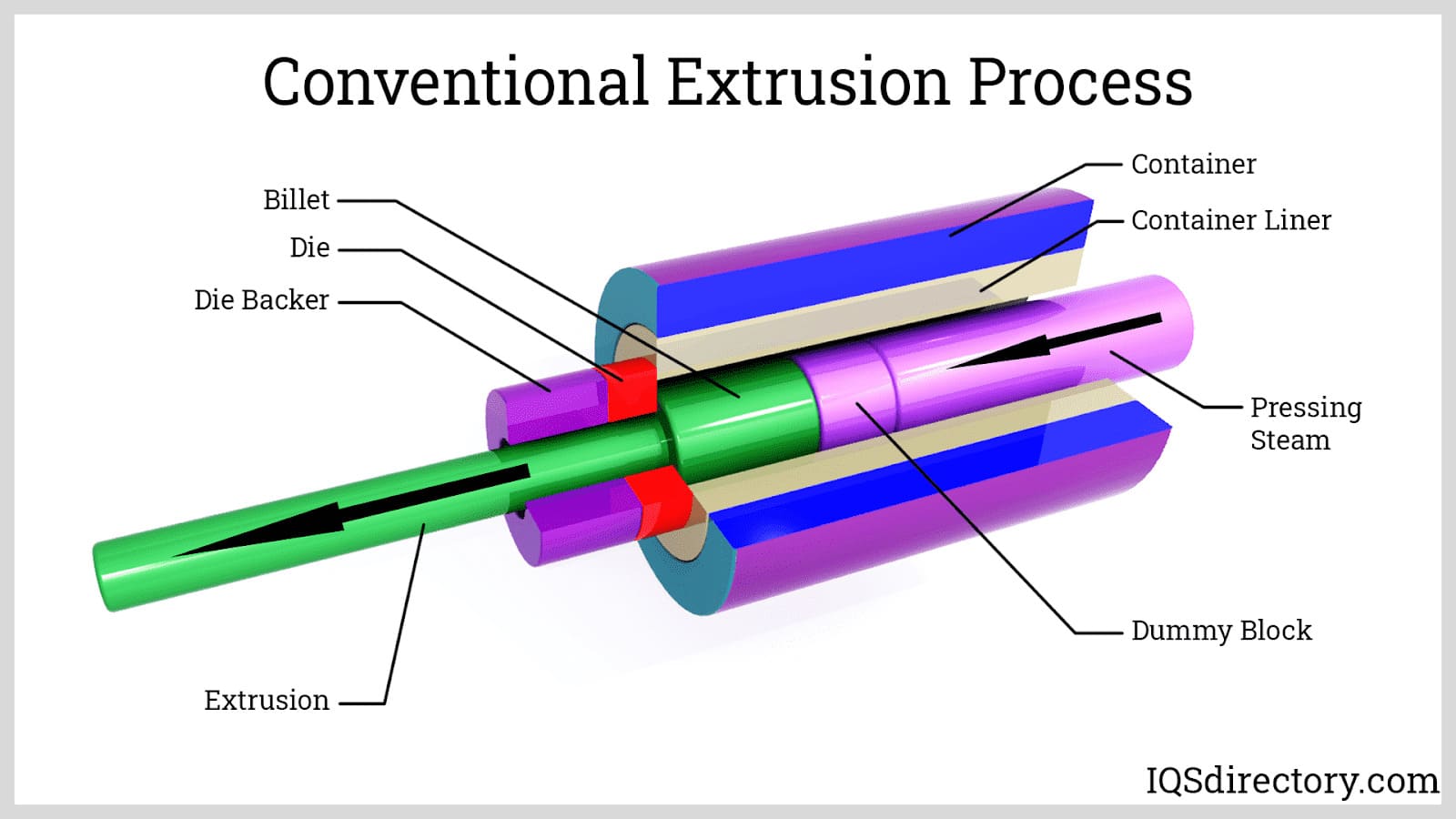

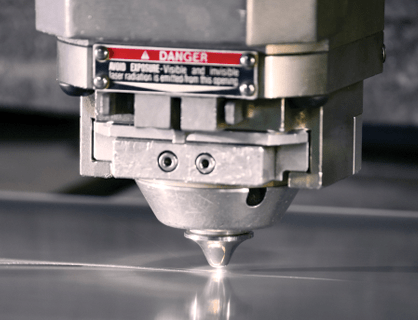

Profiles are produced from softened aluminum billets forced through a die. The two types of extrusion are cold and hot. In both cases, a hydraulic press or ram forces an aluminum billet through the die. The extrusion process requires completing a set of steps where the temperature of the process is closely monitored.

Preparing the Die

The first step in the process is the creation of the die, which is a round piece of hardened steel. To ensure even metal flow and maximize the die's life, it is heated to 932 °F (500 °C) before being loaded into the extruder.

Heating the Billet

For hot extrusion, the billet, which is a few feet in length, is heated to a point where it is soft but not molten, up to 932 °F (500 °C).

Loading the Billet

Before the billet is loaded into the extruder, a release agent is applied so that the soft aluminum moves through the die smoothly and evenly.

Applying the Pressure of the Ram

The hydraulic ram of an extruder can apply 15,000 tons of pressure as it slowly moves the billet toward the die. During the ram's movement, pressure builds as the softened billet expands to fill the walls of the extruder.

Aluminum Emerging from the Profile

The increasing pressure forces the softened aluminum through the die. The emerging shape is the full form of the profile.

Runout Table

When the extrusion exits the die, it is gripped by a puller that guides it along the runout table at its exit speed. The profile is quenched and uniformly cooled on the runout table using water or fans placed along the table.

Shearing

Once the extrusion reaches the end of the runout table, it is sheared for ease of handling and moved on to the next step. Every aspect of the extrusion process includes a close and careful monitoring of the extrusion's temperature to ensure the quality of the extruded product.

Cooling Room

Although the extrusions have been cooled, they are not sufficiently cooled to be fully processed. For further cooling, they are moved to a cooling room, where they remain until they reach room temperature.

Stretching

During the extrusion process, the profile's natural twisting and curving must be corrected by stretching. The process requires that both ends of the extrusion be tightly gripped and pulled until it is straight and meets design specifications.

Finishing

The table length extrusions that have been cooled, stretched, and hardened are ready to be trimmed and cut into usable lengths, normally eight to twelve feet. At the point of finishing, the extrusions match the necessary tolerance of their design and are sufficiently tempered. For further tempering, the extrusions are moved to an aging oven.

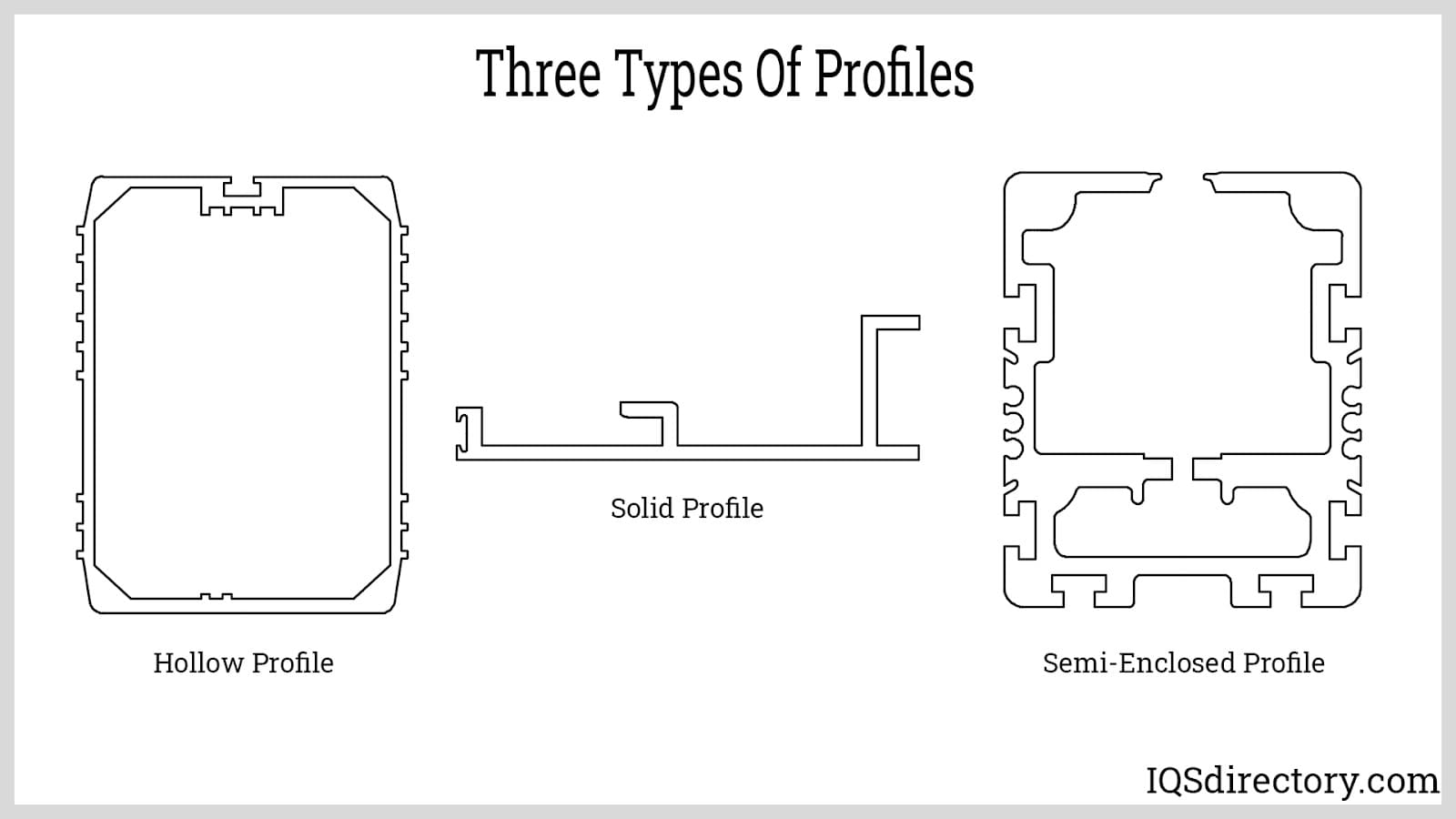

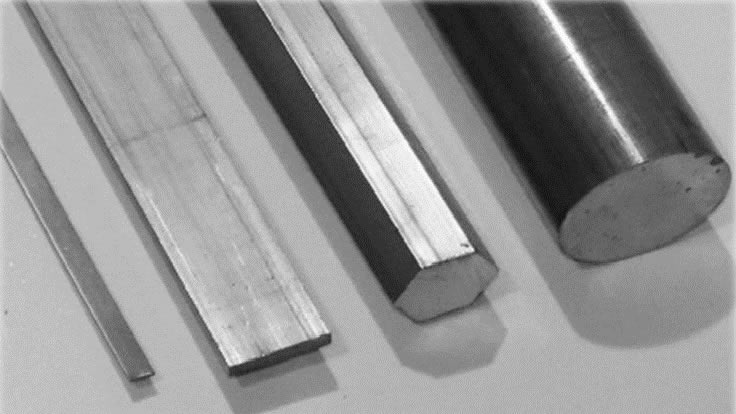

Types of Profiles

The determination of what profile to use is dependent on the application for which it is designed. Profiles come in different thicknesses, types of aluminum, and shapes, making them highly adaptable and versatile, and are manufactured from several deformable aluminum alloys.

Hollow Profiles

Hollow profiles have a cross-section that forms a hollow cavity.

Solid Profiles

Solid profiles are completely open, with no closed sections, and are available in many different forms.

Open End Profiles

Open-end profiles are a combination of hollow and solid profiles.

Semi-Enclosed Profiles

Semi-enclosed profiles are partially open and partially closed cavities, such as a rectangle profile with an entrance on one end. All forms of profiles are required to meet specific geometrical tolerances and dimensions, which are defined by the computer rendering.

Categories of Difficulty for Profiles

All forms of profiles are required to meet specific geometrical tolerances and dimensions, which are defined by the computer rendering.

- Shape Factor – The shape factor is the area of all surfaces of the profile

- Complexity – The complexity of profiles begins with the letter A, the least complex, and continues to the letter N, the most complex.

- Maximization of Aluminum – The maximization of a profile relates to the most efficient use of aluminum.

- Price – The price of a profile directly relates to its complexity.

Choosing the Proper Aluminum Profiles Manufacturer

To make sure you have the most productive outcome when purchasing Aluminum Profiles from an Aluminum Profiles Supplier, it is important to compare at least 4 or 5 Companies using our list of Aluminum Profiles manufacturers. Each Aluminum Profiles Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Aluminum Profiles business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Aluminum Profiles companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services