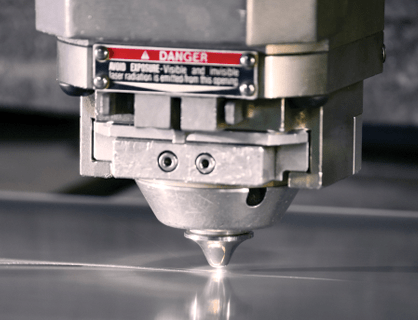

The aluminum extrusion process is a precise method for creating aluminum profiles by forcing soft aluminum billets through a die using a hydraulic press or ram. The force of squeezing the softened aluminum through the die profile enhances its strength and durability. Aluminum extrusion can be hot or cold, determined by the type of aluminum and how the extrusion is completed. Read More…

Serving the aluminum extrusions world from Cleveland, Ohio, Talan Products specializes in a range of aluminum extrusion products and services.

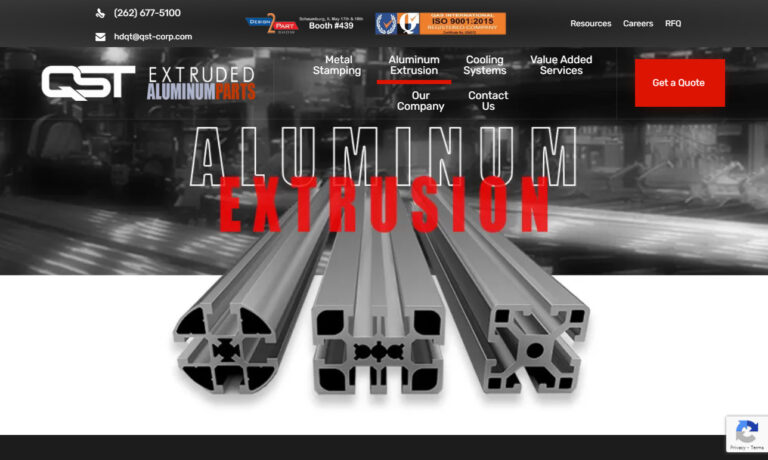

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our aluminum extrusions follow guidelines of up to 6 inches in diameter and...

Since 1986, GSH Industries has offered on time delivery and competitive pricing. With over 40,000 square feet of manufacturing, we offer aluminum extrusion products and services.

Dajcor Aluminum is the leading North American supplier of extruded, fabricated/machined, anodized and assembled components to the automotive, renewable energy, transportation, rail, marine, building trades, military, medical architectural and wall partition systems, office furniture, emergency vehicle and consumer product industries. Dajcor is an aluminum extrusion company with complete value add ...

More Aluminum Extruder Manufacturers

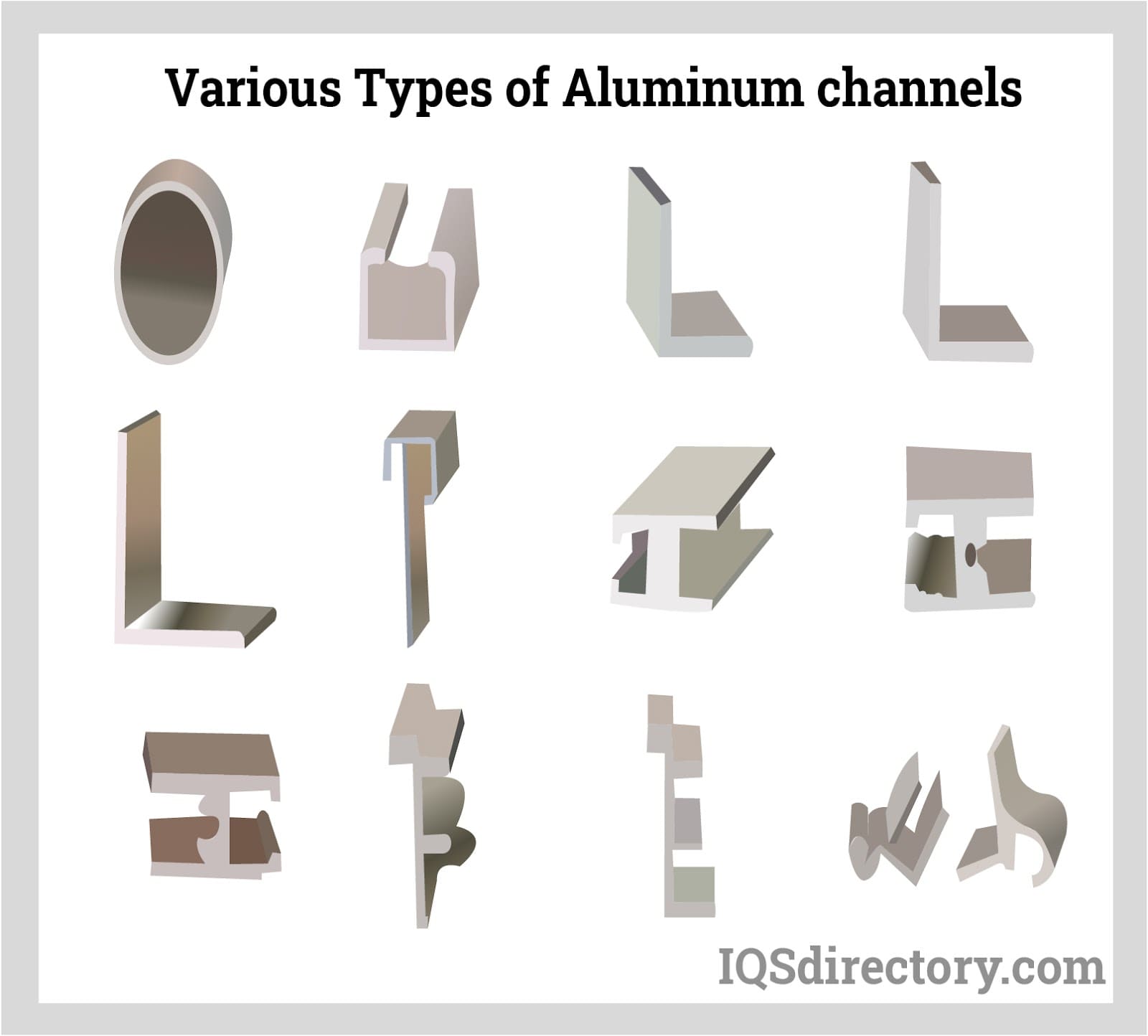

Extruded Shapes

Various aluminum shapes can be configured using extrusion to fit any dimensions or requirements. The choice of shapes is determined by the final use of the extruded product, which can range from I beams to simple right angles. The versatility and adaptability of the extrusion make it possible to engineer every aluminum extrusion to precisely fit an application.

Angles

Angles are one of the most common types of aluminum extrusions. They can have sharp or rounded corners and come in various lengths and thicknesses.

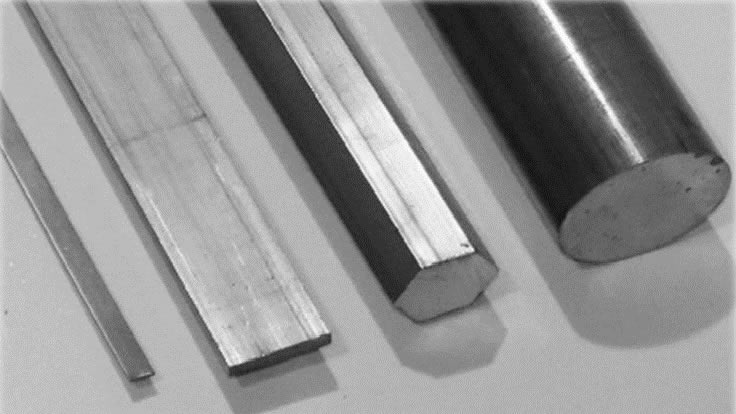

Bars

Structural support bars are produced in rectangular, square, or hexagonal configurations. A key factor in their extrusion is their thickness, which must be closely monitored to fit the final use.

Channels

Channels are another widely used extruded aluminum product with endless uses, from edging for windows and doors to handrails for railings and decorative accents for architecture.

I Beams

Aluminum I beams are an essential part of construction projects and have found increased use in modern structures due to their light weight and strength.

Tees

Tees are produced much like angles with sharp or rounded corners. They seal off an edge to add a finishing touch or cover a rough, uneven surface.

Tubes

Aluminum tubes have gained increasing popularity due to their light weight and strength. They are used to move fluids, connect devices, and support other products. Aluminum extruded tubing comes in a wide selection of diameters and sizes, making them flexible enough to fit any application or process.

Zees

There are several types and shapes of extruded aluminum Z shapes, which are used as eagle clips, rails, and support bars. Z-shaped extruded aluminum can have the various parts of the shape adjusted using different lengths and thicknesses. In some ways, the Z shape is one of the more adaptable and versatile aluminum extrusions.

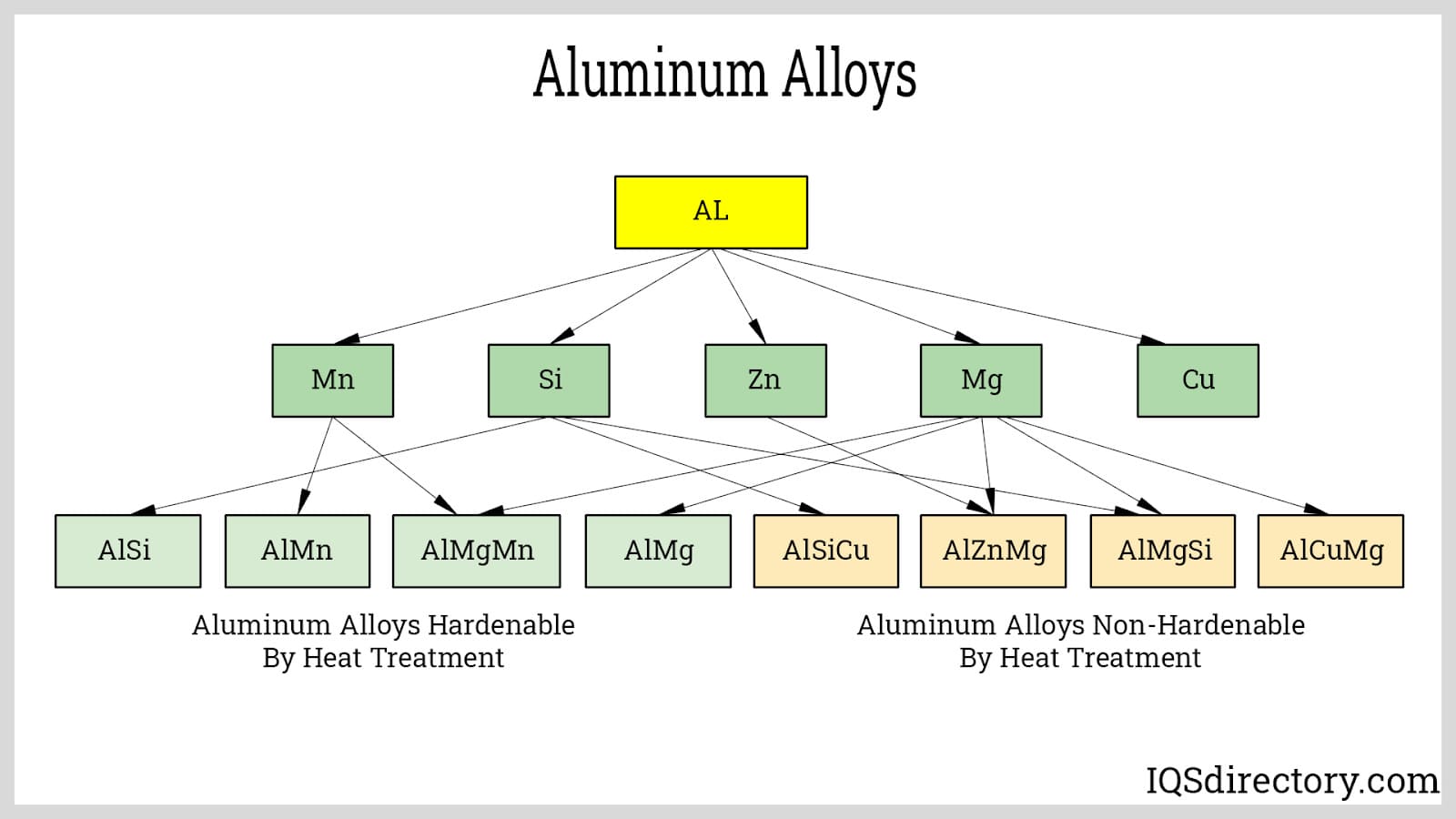

Aluminum Used for Aluminum Extrusion

The term aluminum refers to an assortment of alloys used for extrusion. Each alloyed type is designated by a four-digit number, which indicates its alloying elements, strength, corrosion resistance, formability, and weldability. The two types of alloys are cast and wrought, with cast aluminum having a lower melting point and strength, while wrought aluminum alloys are stronger and more resilient.

The difference between cast and wrought aluminum can be seen in how they are numbered. Each type consists of four digits. The third and fourth digits of cast aluminum alloys are separated by a decimal point, while wrought aluminum alloys do not have a decimal point. This distinction makes it easy to identify the types. Extrusion uses a wide variety of aluminums, which is determined by how the extrusion will be used and how it will be processed.

Aluminum 1100

Aluminum 1100 is pure aluminum without any alloys. It is very soft, ductile, and pliable, making it easy to extrude into many shapes.

Aluminum 3003

Aluminum 3003 is an alloy of aluminum and manganese. It is stronger than 1100 and is commonly used in the production of heat exchangers.

Aluminum 6063

Aluminum 6063 contains magnesium and silicon and is referred to as architectural aluminum since it can be extruded into complex, intricate designs and shapes. It is normally extruded for decorative applications.

Aluminum 6061

Aluminum 6061 is a high-strength aluminum with a tensile strength of 35,000 psi to 38,000 psi. It is easily extrudable and weldable, making it ideal for car and truck frames and pipelines.

Aluminum 7075

Aluminum 7075 is one of the strongest, most resilient, durable, and long-lasting of the various aluminum alloys. It comprises aluminum, copper, and zinc with small amounts of magnesium, iron, silicon, manganese, chromium, and titanium. In some respects, Aluminum 7075 is comparable in strength to low-grade steels. Due to its strength and endurance, it is used for heavy industrial projects such as aircraft and military equipment.

Advantages of Aluminum Extrusion

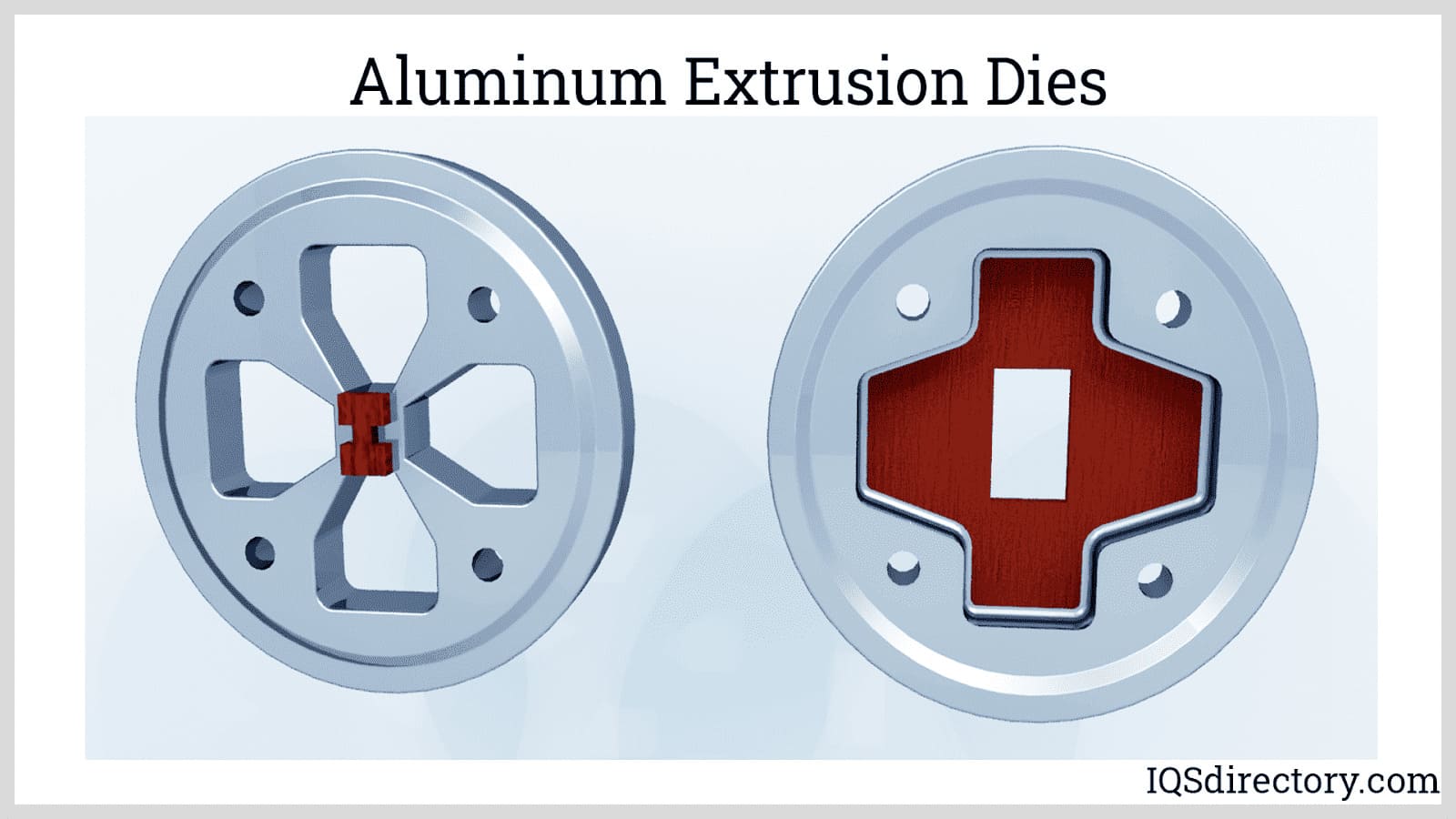

The wide variety of aluminum and the endless number of extrusion dies make aluminum extrusion one of the most popular manufacturing processes. It is used to produce components with complex cross-sections and intricate designs. The advantages of aluminum extrusion include:

- Superior strength-to-weight ratio

- Variety of available materials

- Suitable for many applications

- Corrosion-resistant

- Thermal and electrical conductivity

- Cost-effective

Choosing the Aluminum Extruders Manufacturer

To make sure you have the most positive outcome when purchasing Aluminum Extruders from an Aluminum Extruders Manufacturer, it is important to compare at least 6 Companies using our list of Aluminum Extruders suppliers. Each Aluminum Extruders Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Aluminum Extruders business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Aluminum Extruders companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services