Daymond Aluminum

Daymond AluminumRequest A Quote

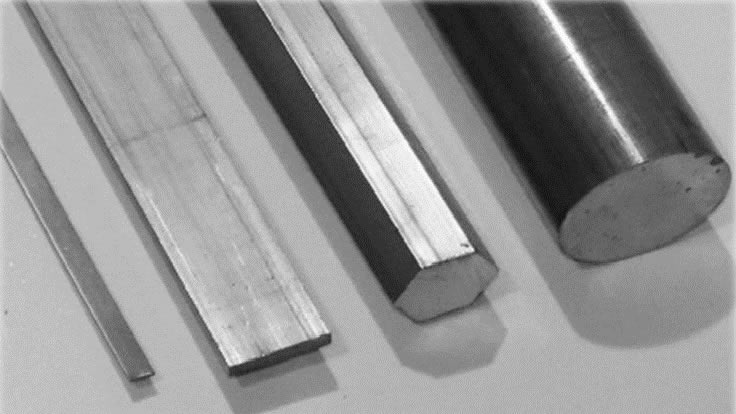

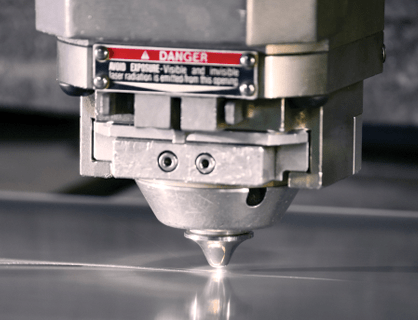

Chatham, ONDaymond Aluminum is a trusted provider of high-quality aluminum extrusion products and services. With a strong emphasis on innovation, precision, and customer satisfaction, Daymond Aluminum has established itself as a reliable partner in the aluminum extrusion industry. The company operates advanced manufacturing facilities equipped with state-of-the-art machinery and technology. This enables Daymond Aluminum to deliver exceptional precision and efficiency in the production of aluminum extrusions. Their team of skilled engineers, designers, and technicians works closely with clients to understand their specific requirements and collaboratively develop custom extrusion solutions. Daymond Aluminum offers a wide range of aluminum extrusion profiles, catering to diverse industries and applications. From standard shapes to complex geometries, their capabilities allow for the creation of customized profiles that meet the unique needs of their customers. With a focus on quality and precision, Daymond Aluminum ensures that every extrusion is produced with tight tolerances, excellent surface finishes, and precise dimensions. In addition to their manufacturing capabilities, Daymond Aluminum provides comprehensive services to support their customers throughout the entire process. Their experienced team offers expertise in design optimization, prototyping, and finishing options, enabling clients to achieve the desired functionality and aesthetics of their extrusion projects. Whether it's a small-scale prototype or a large production run, Daymond Aluminum is equipped to handle projects of all sizes and complexities. Daymond Aluminum's extrusion products find applications across various industries, including automotive, aerospace, construction, electronics, and more. Their aluminum extrusions are utilized in a wide range of products and components, such as architectural elements, heat sinks, frames, enclosures, and structural components. Daymond Aluminum understands the specific requirements and performance demands of each industry and works closely with clients to deliver tailored solutions that meet their exact specifications. Quality is of utmost importance to Daymond Aluminum, and they adhere to rigorous quality control measures throughout the manufacturing process. Every aluminum extrusion undergoes comprehensive testing and inspection to ensure it meets the highest industry standards. This commitment to quality ensures that customers receive extrusions that are reliable, durable, and meet their specific performance requirements. Daymond Aluminum also prioritizes sustainability and environmental responsibility. They implement eco-friendly practices in their operations, such as recycling aluminum scraps and optimizing energy consumption. By incorporating sustainable practices, Daymond Aluminum contributes to minimizing their environmental impact and promoting a greener future. Customer satisfaction is at the core of Daymond Aluminum's business philosophy. They are dedicated to providing exceptional customer service, timely delivery, and effective communication throughout the project. Daymond Aluminum's responsive and knowledgeable team is always available to address customer inquiries, provide technical support, and offer guidance to ensure a seamless and successful project outcome. In summary, Daymond Aluminum is a reputable provider of aluminum extrusion products and services. With their advanced facilities, technical expertise, and comprehensive range of services, Daymond Aluminum delivers customized solutions that meet the highest standards of quality and precision. Clients can rely on Daymond Aluminum to provide them with top-quality aluminum extrusions, exceptional service, and reliable support throughout the entire project journey.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services