Lynch Metals, Inc.

Lynch Metals, Inc.Request A Quote

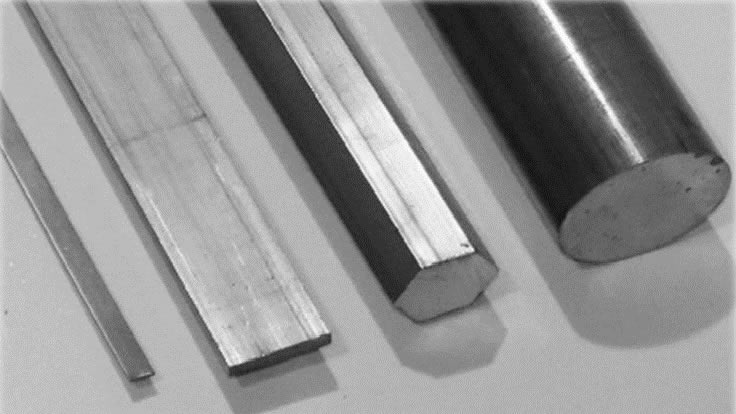

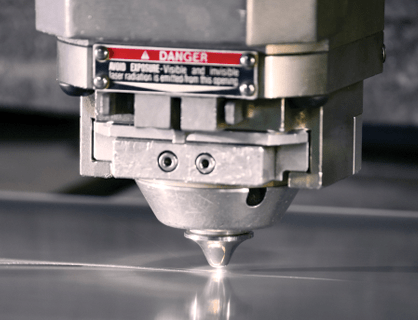

Union, NJLynch Metals, Inc. is a leading manufacturer and distributor of high-quality Aluminum Extrusions, offering a comprehensive range of products and exceptional service capabilities. With a strong presence in the industry, Lynch Metals has built a reputation for excellence, reliability, and innovation since its establishment. At Lynch Metals, our core expertise lies in the production and supply of aluminum extrusions, serving diverse industries such as automotive, aerospace, construction, electronics, and more. We understand the unique requirements and specifications of our customers and strive to provide customized solutions that meet their exacting standards. Our state-of-the-art manufacturing facilities are equipped with advanced technology and machinery, enabling us to deliver precise and consistent aluminum extrusions of various shapes, sizes, and complexities. We work with a wide range of aluminum alloys, including 6061, 6063, and 7075, among others, to offer versatility and meet specific application needs. One of our key strengths is our highly skilled and experienced team of engineers, designers, and technicians who possess deep knowledge of aluminum extrusions. They collaborate closely with our customers from the initial concept stage through to the final product, ensuring seamless integration and optimum results. We leverage computer-aided design (CAD) and computer-aided manufacturing (CAM) software to streamline the production process and enhance efficiency. At Lynch Metals, we take pride in our commitment to quality. Our aluminum extrusions undergo rigorous testing and inspection procedures at every stage of manufacturing to ensure they meet or exceed industry standards. We are ISO 9001 certified, which reflects our dedication to maintaining the highest levels of quality control and customer satisfaction. In addition to our superior product offerings, we provide comprehensive value-added services to enhance the customer experience. Our capabilities include precision cutting, machining, drilling, bending, welding, anodizing, and powder coating. These services enable us to deliver fully finished aluminum extrusions that are ready for assembly, saving our customers time and resources. As a customer-centric organization, Lynch Metals is known for its exceptional service. We understand the importance of timely delivery and offer efficient logistics solutions to ensure prompt shipment of orders, whether they are small prototypes or large-scale production runs. Our customer support team is responsive, knowledgeable, and always ready to assist with technical inquiries, product recommendations, and order tracking. Lynch Metals is committed to sustainability and environmental stewardship. We adhere to responsible manufacturing practices and actively promote the use of recyclable aluminum in our extrusion processes. By focusing on energy efficiency and waste reduction, we strive to minimize our carbon footprint and contribute to a greener future. In summary, Lynch Metals, Inc. is a trusted industry leader in the manufacturing and distribution of aluminum extrusions. With our extensive product range, cutting-edge technology, exceptional service capabilities, and commitment to quality and sustainability, we are the preferred choice for customers seeking reliable solutions for their aluminum extrusion needs.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services