PCR Technologies

PCR TechnologiesRequest A Quote

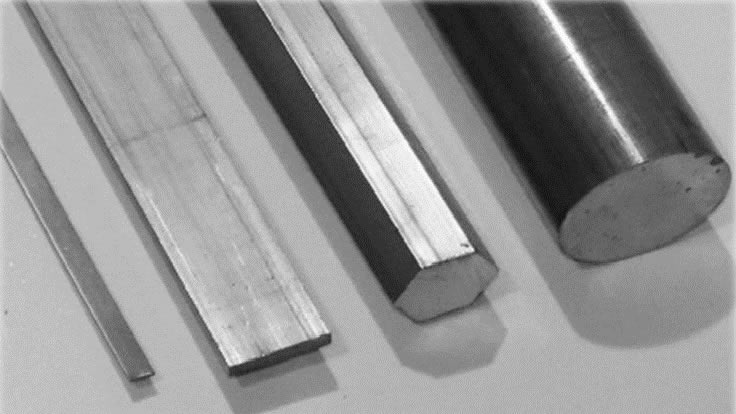

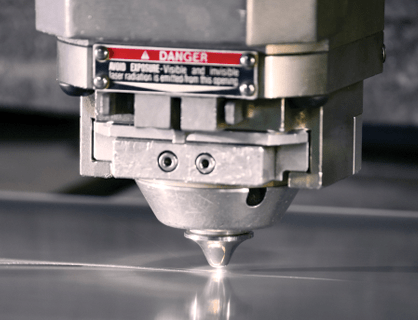

Fairfield, NJPCR Technologies is a dynamic and innovative company specializing in the manufacturing and distribution of Aluminum Extrusions. With a passion for excellence and a commitment to delivering superior products and services, PCR Technologies has established itself as a trusted leader in the aluminum extrusion industry. At PCR Technologies, we pride ourselves on our ability to provide a diverse range of high-quality Aluminum Extrusions tailored to meet the unique needs of our customers. With state-of-the-art facilities and cutting-edge technology, we possess the expertise and resources to produce extrusions in various shapes, sizes, and finishes. Whether our clients require standard profiles or custom designs, we work closely with them to develop solutions that precisely match their specifications. Our Aluminum Extrusions products find wide-ranging applications across multiple industries, including automotive, aerospace, construction, electronics, furniture, and many others. The versatility of aluminum as a material, combined with our advanced manufacturing capabilities, allows us to create extrusions that excel in terms of strength, durability, and corrosion resistance. Our extruded profiles offer exceptional dimensional accuracy, surface finish, and tight tolerances, making them ideal for both structural and decorative purposes. One of the key differentiators of PCR Technologies is our strong commitment to providing comprehensive service capabilities alongside our aluminum extrusion products. We understand that each customer has unique requirements, and we strive to be their trusted partner throughout the entire process. Our team of skilled engineers and technicians works closely with clients to assist in product design, prototyping, and optimization, ensuring that the final extrusions meet or exceed expectations. In addition to our manufacturing expertise, PCR Technologies offers a range of value-added services that enhance the functionality and aesthetics of our aluminum extrusions. These services include precision cutting, CNC machining, drilling, tapping, welding, surface finishing, and assembly. By providing these secondary operations, we offer our customers the convenience of receiving fully machined and finished extrusions, ready for immediate integration into their applications or assemblies. Quality is at the core of everything we do at PCR Technologies. We adhere to stringent quality control procedures at every stage of the manufacturing process, ensuring that our aluminum extrusions meet the highest industry standards. Our commitment to quality is underpinned by our ISO 9001 certification, demonstrating our dedication to consistently delivering products of exceptional quality, reliability, and performance. Customer satisfaction is a top priority at PCR Technologies. We strive to build long-term partnerships with our clients by providing exceptional customer service, timely communication, and efficient order fulfillment. Our sales and support team is readily available to address any inquiries, provide technical assistance, and ensure a seamless experience for our customers from start to finish. PCR Technologies is committed to sustainability and environmental responsibility. We actively seek ways to reduce waste, minimize energy consumption, and employ environmentally friendly practices throughout our operations. Our aluminum extrusions are recyclable and contribute to the overall sustainability goals of our customers and the industries we serve. In summary, PCR Technologies is a forward-thinking company specializing in the production and distribution of high-quality Aluminum Extrusions. With our dedication to innovation, technical expertise, and customer-centric approach, we are the preferred choice for businesses seeking reliable, customized, and sustainable aluminum extrusion solutions.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Nickel

Nickel Magnets

Magnets Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services